Short Comings |

Details |

Fix |

| Propedal system is position sensitive, not speed sensitive |

As pressure increases in the reservoir the

valve gets stiffer |

Replace with the SSD speed sensitive custom

valved shimmed four port piston valve, prevents bottoming without

high speed harshness |

| Propedal adjuster creates too much harshness when increased |

Too much reservoir pressure force on valve

creates low to mid speed harshness when increased |

Remove Propedal and replace with low speed

adjuster needle and SSD valve. |

Boost valve is position sensitive

(gets stiffer when shaft is deeper in stroke, good for bottoming

bad for square edged) |

Reservoir pressure assisted end of stroke

position sensitive compression pop it valve |

Replace with the SSD speed sensitive custom

valved shimmed four port piston valve, prevents bottoming without

high speed harshness |

High speed Compression too soft

(generically valved for all linkages) |

Generically valved to work with over stiff

propedal |

Revalve with Midvalve style 2 stage custom

shimmed for leverage and type of riding. |

High speed rebound too slow

(generically valved) |

Generically valve to best compromise all

spring rates |

Revalve with 2 stage custom shimmed for

stroke and spring rate. |

| No Low speed compression adjuster |

Propedal valve only provides high speed

damping |

Use the Propedal knob to control the newly

installed low speed needle to provide low speed adjustment,

15 clicks |

| Reservoir volume too small, causes pressure ramp-up in middle

and end of stroke |

Pressure can ramp-up to nearly 1500 psi,

this is what controls the boost valve! |

Modified reservoir reduces pressure ramp-up

to under 400 psi, extended reservoir keeps it around 200 psi |

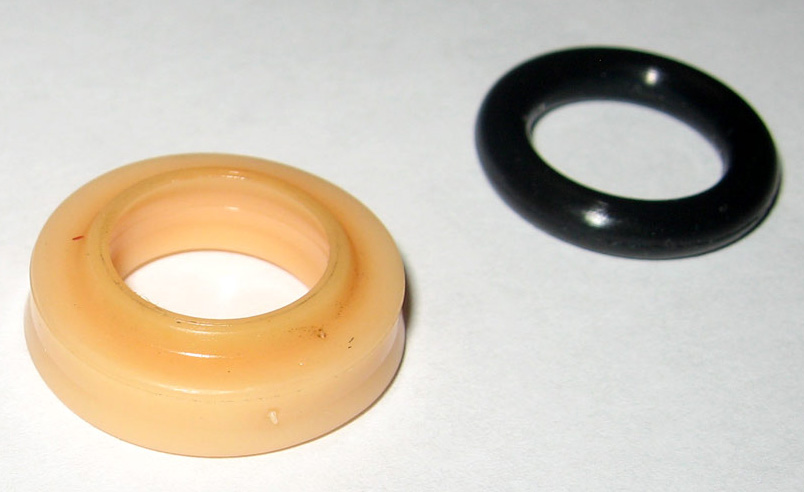

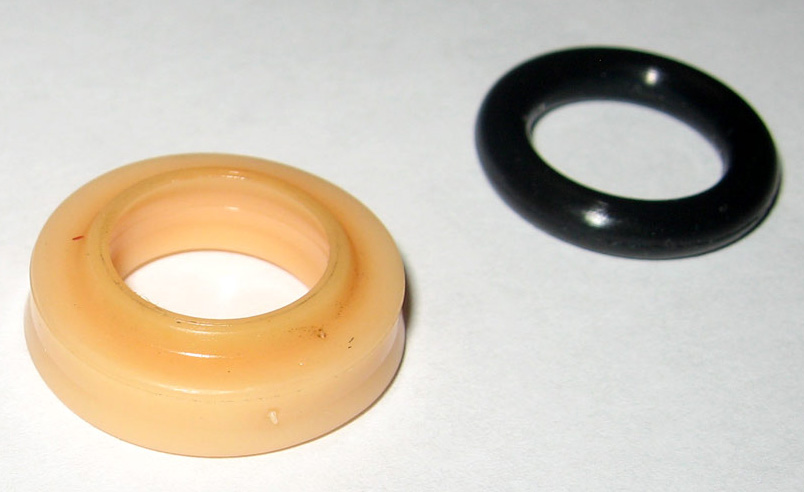

| Shaft seals have too much stiction |

Standard buna o-ring with high friction urethane grip dust

seal

|

Double lip Viton oil seal, oil wiper barrier and mud and

dust scraper system

|

Bottom-out bumper in effective for end of stoke

ramp-up

(anti-clunk only) |

squats outwardly with no constraint, no ramp-up resistance

|

Shape factor, ramps-up progressively as it conforms and fills

the shape of the spring inner diameter

|

__

__